The majority of attractive PV locations are impaired by soiling losses, which refers to loss in power due to dirt, dust, snow and other particles covering the surface of the PV module. Dust can originate from a number of sources, including pollution resulting from wind, vehicular activities and so forth.

This article, based on a recent Solarplaza webinar (‘Quantification of module soiling: Data analysis and innovative methods’ - full recordings & slides available now), comes in preparation of the Solar Asset Management Europe conference and networking platform, which is set to take place on the 07-08 of November in Milan, Italy. This conference is a must-attend event fully dedicated to optimization of the operational phase of PV plants and portfolios. For more information, regarding the event please visit our event website.

The European solar industry is now, more than ever, faced with a new landscape of both challenges and opportunities, such as new business models, consolidation, grid balancing and larger exposure to the electricity market. In dealing with these challenges, and capturing the opportunities in new markets, proper asset management makes a real difference when it comes to the profitability and sustainability of success.

Soiling loss & the measuring of its effect

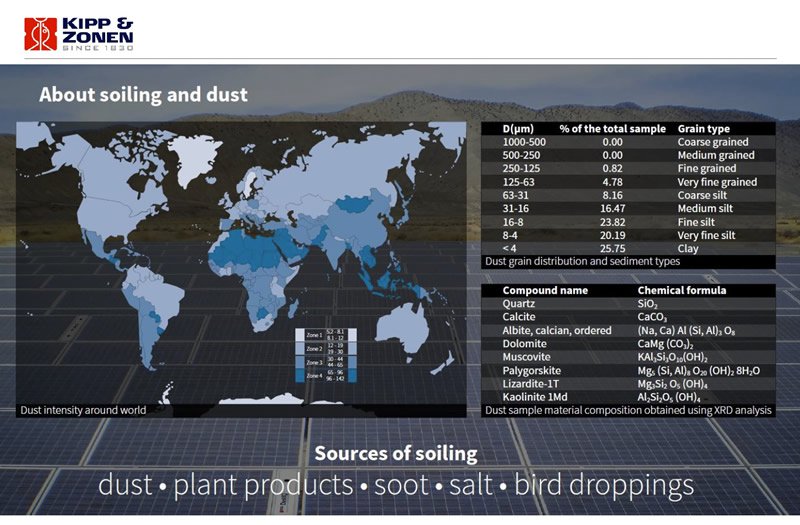

Soiling loss is dependent on location. The accumulated dust over time amplifies the soiling effect, which impacts the overall energy generated by the PV module on a weekly basis. A number of factors influence soiling, such as soil intensity, plant size, tilt of the model and local climate. Areas experiencing a higher amount of rain tend to account for a lower power loss percentage since rain has a cleaning effect. Therefore, it is not striking that dust intensity as well as soiling effect are relatively worse in desert-like parts of the world (as demonstrated in Figure 1).

Soiling is measured using Transmission Loss (TL). The frequency of measurement is determined by various factors including size, terrain and wind uniformity. Moreover, soiling ratio is subject to change throughout the day, depending on the position of the sun and the angle of solar radiation; the lower the sun, the worse the effect of soiling and hence the greater the amount of loss.

The conventional methods to measure soiling work relatively well from a technical stance and are always comprised of two panels, one of which is kept clean - either using a robot or manual labour - while the other is left subject to dirt. Donald van Velsen and his team at Kipp & Zonen have created a new technology to measure soiling called Dust IQ (figure 2), which is more affordable than the existing technology and requires less maintenance. The Dust IQs weigh around 4kgs and are daisy-chainable enabling operators to connect multiple Dust IQs in order to form one string throughout the entire system. Dust IQ utilises Optimal Soiling Measurement (OSM) Technology, which - every minute - measures the sun reflection from below that can then be translated into soiling loss data in real time. Dust IQ, as the name suggests, is solely sensitive to dust and not snow. This technology-expansion is expected to be commercially available at the beginning of 2018.

Quantification of soiling using advanced data analysis

Gerhard Mütter and his team from Alternative Energy Solutions have also developed a new method to measure soiling, using advanced data analysis called AES PIT (Figure 3). This is essentially an algorithmic toolbox for iterative machine learning. These algorithms are developed based on actual field data and thus consider environmental factors. Nonetheless, the resulting numbers and algorithms were mathematically adjusted to avoid any pitfalls they may be subject to. The primary difference between normal monitoring and utilising advanced data analysis is best described as the difference between having a picture of the plant, which is a momentary snapshot, versus a movie of the plant, which displays every solitary occurring that is happening during the operation of the plant. Additionally, by means of data mining through AES PIT, the soiling amount can be isolated for every small unit, which is used to generate a cost-benefit analysis in order to decide whether it is necessary to clean the panels or not. Solar PV panels differ in the accumulation of dust depending on the angle, type of glass used, coating and framing. For instance, most thin film modules do not have any frame, absence of which allows rain to wash away the dirt. In fact, a case study of a 250 MW PV asset, conducted by Gerhard Müttert, shows that half a litre of rain for the duration of 15 minutes has a resembling effect to manually cleaning the panels.